A Warehouse Management System is right for you if…

- You want to manage every item and its stock count in your warehouse

- You want to find out quickly where an item is located in the warehouses

- You want to automate the process of receiving and fulfilling items from the warehouse

- You have multiple warehouses and trucks

- You want to keep track of perishable items

- You use trucks to deliver items to other businesses

- You want to issue invoices from the truck

- Truck drivers want to request items-transfer to trucks from the warehouse

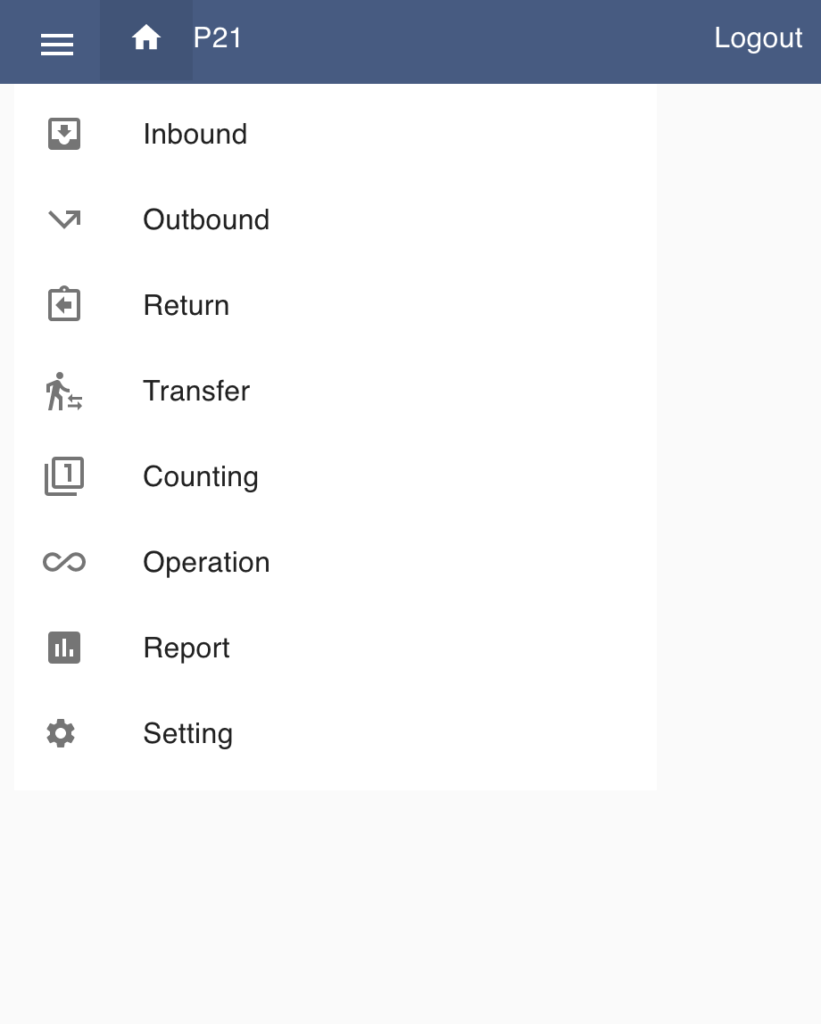

Barcode Your Inventory

Process receive, putaway, and return faster and precisely. Pick customers’s orders quicker and accurately. You can use barcode scanner device or simply your own mobile phone as scanner.

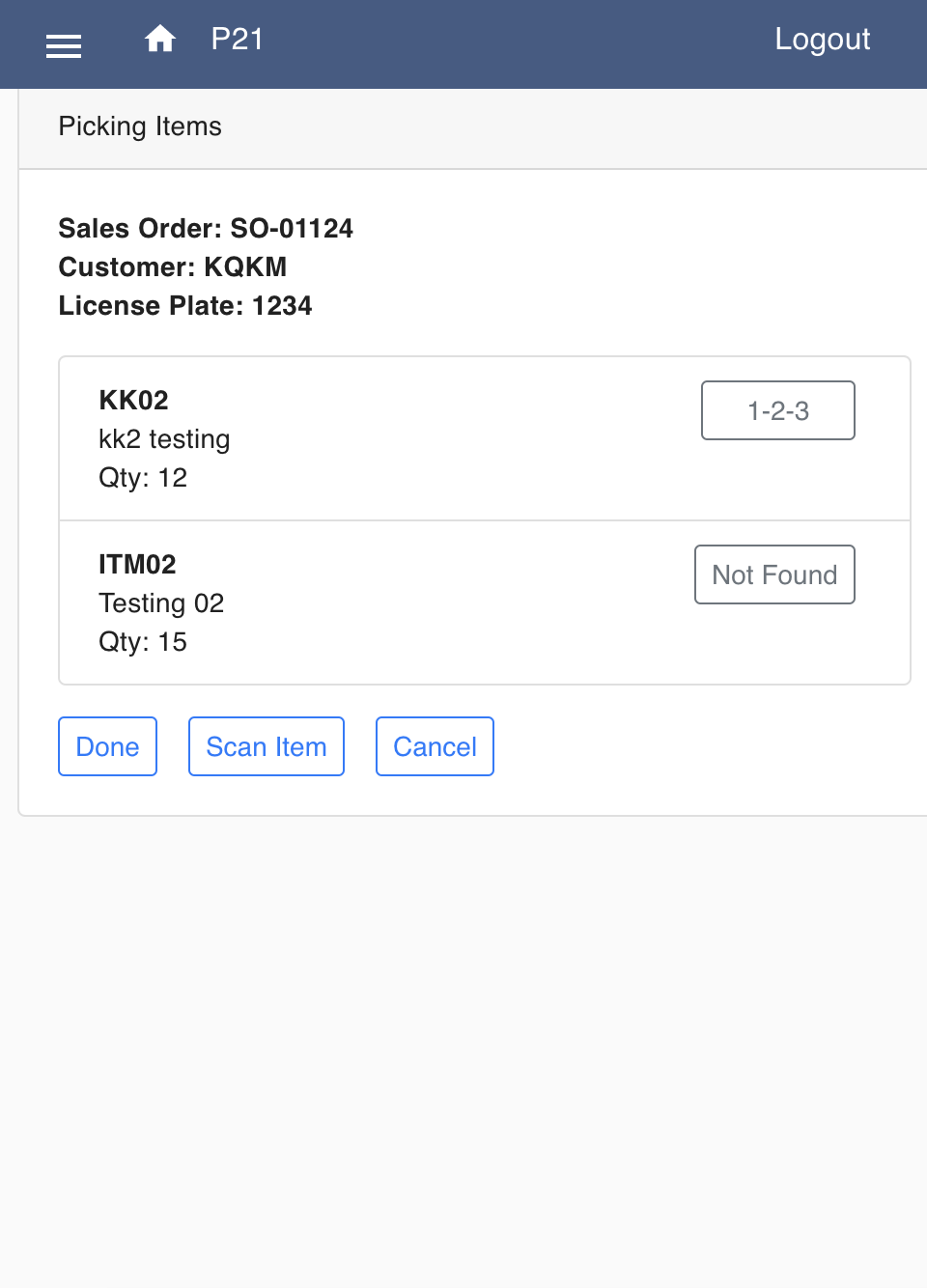

Efficient Order Picking

With guided item pick, pick order quickly and accurately. By improving picking accuracy, your business can avoid unnecessary errors which may affect customer claims, redeliveries, and other issues.

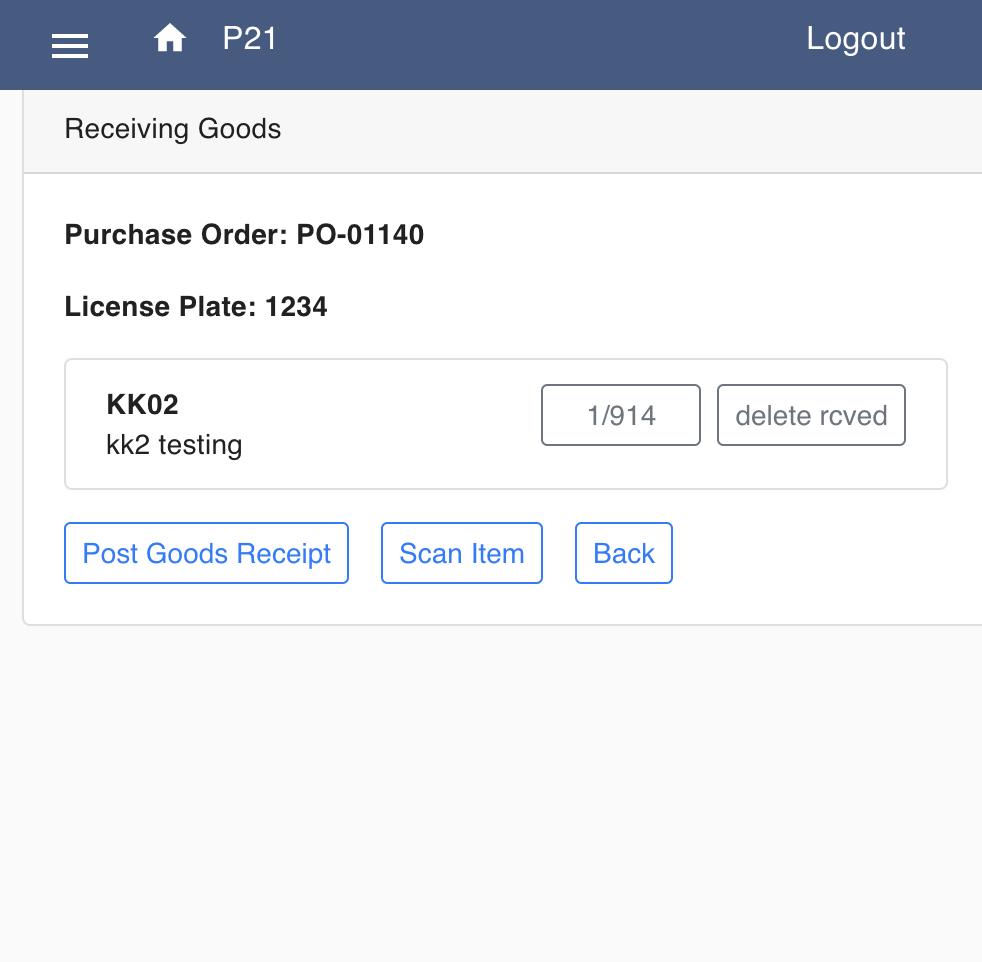

Receive and Putaway

Receive goods in the receiving zone and putaway to the specific storage bin quickly and efficiently. This simplifies the process of storing items, reduces the risk of misplacing or losing items, and keeps your warehouse clean and organized.

Return, Transfer & Cycle Count

Support return to inventory, discard, and return to supplier. Transfer goods from one warehouse location to another. Allow stock cycle count by using both directed and blind count methods.

Storage Management

Manage storage efficiently using properly configure the warehouse layout and dividing the warehouse space in various zones, sections, row, rack, stack, level, and bin. Arrange best selling items together for effectively fulfilling the customers orders.

Batch and Expiration

Allow to receive and pick items according their batch (or lot) and expiration date. This allows effective management of perishable and healthcare products in the warehouse.

Enterprise grade – ready for Retail, eCommerce, Warehousing…

Faster Order Fulfillment

Improve item picking time with the visibility of accurate stock count and location of the item in the warehouse. With guided picking improve picking cycle time. Manage multiple warehouse locations near your customers to minimize the shipping time.

Fulfillment Accuracy

Warehouse management usually focuses on speed and accuracy. Achieving speed many times comes with high cost of “errors”. This may lead to more returns, dissatisfied customers, costly restocking, and re-delivery procedures. So, accuracy is equally important for a warehouse manager as speed.

Reduced Cost

A warehouse management system software can provide a better visibility of what products leaving the warehouse. This will help you to optimize the arrangement of the warehouse so that you can store most often ordered items close the loading area. This will shorten your order pickup time and reduce the cost.

Increase Profitability

Using WMS you can run your analytics faster which may help you in many ways. With the help of analytics, you can replenish products as need basis. You can also predict the need for the stock for items in the short run and order those items in advance. This will help reduce your inventory cost and increase profitability.

Replenish Inventory in Time

Knowing what is selling and rate of stock outflow, you could determine the rate of replenishment of those products. Using analytics to assess each product’s monthly selling trend, you can set up restocking systems to ensure that stocks are replenished in time, and you are never out of stock.

Built for Small, Medium, and Enterprise

Datamoto WMS is simple, yet powerful. You can use barcode scanner for receiving or picking goods. Or you can use mobile phone as a barcode scanner. If item do not have barcode – you can print one or receive or pick it without barcode. You can handle a small warehouse with few hundreds items to multiple warehouses with thousands of items. It comes with inventory management and order management.

Datamoto WMS is built for manufacturing, eCommerice, warehousing, or for any organization who maintains inventory…

Warehouse Management System for Healthcare

Healthcare clinics and hospitals may not have large inventories and warehouses to store medicine and equipment, but they might have complex requirements of supply chain. The pharmaceutical logistics can be challenging because many medications and medical equipment have specific storage needs, such as refrigeration, lot number, expiration date etc. They are also bound with government regulation where recalls of medications and equipment are very strictly followed. A WMS can help healthcare facilities and distributors of medical suppliers to manage their operations efficiently.

Inventory Management System with WMS

As your business grow, you need to make sure your software systems are integrated, and all the data are synced all the time. This will ensure your multi-warehouse inventory management and ordering systems are in sync to prevent any delays. For a growing business, you should make sure that you have proper software solutions which can drive operation like:

- Create multiple warehouses

- Manage quantity and transfer inventory between warehouses

- Manage dropship orders

- Implement automatic order routing

- Create invoices, packing slips and shipping labels

- Get order notifications

- Access real-time order status