Everything You Need to Know About Purchase Orders

In this blog, we explain what Purchase Orders are, how they work, and how to create an efficient PO system that works perfectly for your needs. This blog post is for educational purpose only.

What is a Purchase Order?

A Purchase Order (PO) is a commercial document issued by a buyer to a seller indicating types, quantities, and agreed prices for products or services. Purchase orders, also known as Spending Management, can be an essential part of enterprise resource planning (ERP) system. Companies use POs for several reasons. Purchase orders allow buyers to communicate their intentions clearly and explicitly to sellers. They may also help a purchasing agent to manage incoming orders and pending orders. Sellers are also protected by POs in case of a buyer’s refusal to pay for goods or services. Spending Management provide benefits in that they streamline the purchasing process to a standard procedure. Commercial lenders or financial institutions may provide financial assistance based on PO documents.

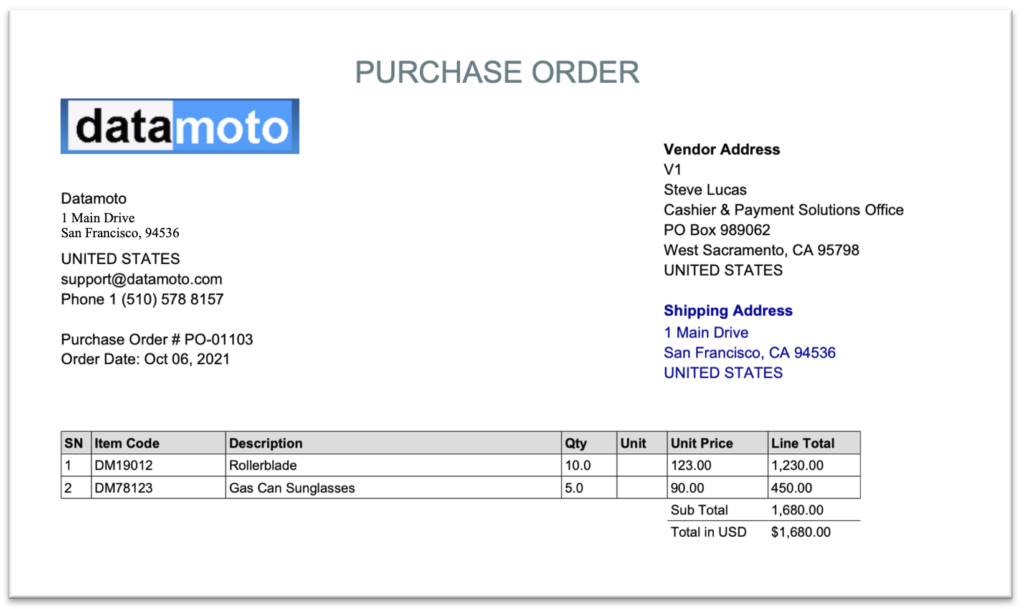

Here is an example of a purchase order document:

How to Create Purchase Orders?

You can create PO using online purchase order software (also known as cloud purchase order tool). To create a PO, you will need following information:

- Issue date

- Products needed and the quantity of each product

- Product details including SKU numbers, model numbers and brand names

- Price of each product per unit

- Delivery date PO number

- Business information including the shipping and billing address, company name and contact information

- Terms for payment, such as “paid upon delivery” or specific payment date options

Purchase Order System and Accounting Software

A PO System is separate from accounting system. A PO System generates bills when it received goods or services from the suppliers. The vendor and supplier also send you the invoices. An accounting system needs the bill and invoice to pay to the supplier.

A small and medium sized business may often need a PO System tool which works with their existing accounting system. DATAMOTO provides inbuilt bills and invoice integration with Quickbooks.

The Key Features of a Purchase Order System?

The Key functionalities of Purchase Order System are described as follows:

- A cloud purchase order system software must allow user to create purchase order for a vendor for items which are existent or non-existent inventory items.

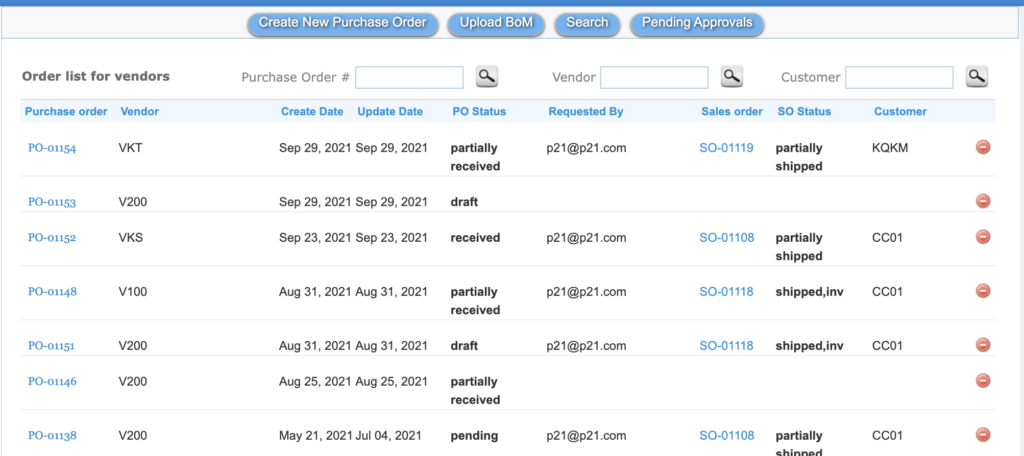

- A PO tracking system must allow to link POs to a Sales Orders to track it. It should clearly state the status of a PO such as: received, partial received, cancelled, etc.

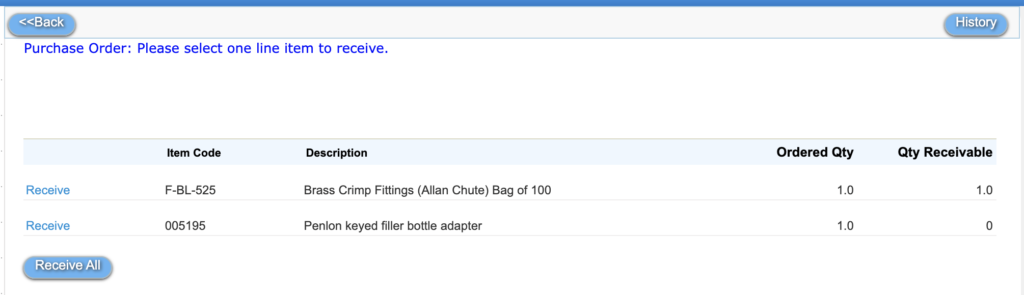

- A PO System must allow to receive full or partial delivery. The Goods receive process should allow user to receive goods to a specific warehouse (inventory location) and generate appropriate bill.

- A PO must allow to generate more than one bill per PO. Also, it should allow to merge all bills to a single bill from a PO even while receiving goods multiple times for the same PO.

- A user-friendly Purchase Order Management System allows uploading bill of materials (BOM) to generate POs for multiple vendors in one click. You can read more on Bill of Materials to Purchase Order.

- The PO System must integrate with inventory control system and sales order management system.

- A PO System must handle returns and auto generates invoices.

- An advance PO System must support multi-level PO approval workflow and should notify pending approvals via emails. It should also allow to approve a PO by email.

- Vendor management and vendor catalog are important functionalities for a Purchasing System if you maintain many vendors.

- A PO System must have dropship order management. Dropship PO is often use by small and medium sized businesses.

- It is important to keep track of invoices and other documents that are received from the vendor. The PP Tracking System must allow attaching documents of document in a PO.

- Spend management functionality enables spend visibility of all buys for quicker invoice processing for better expense management of your business

- An integrated PO System allows generating POs in one click from the inventory stock replenishment alerts.

- User activities on the PO are logged. More on purchase order activity logging

- Purchase order management software should support multi-currency to enable procurement from foreign countries.

- Purchase order software should integrate to accounting system like Quickbooks so that bills and invoices are regularly synchronized.

- For field service, a PO Software must allow to generate POs and attach to work order.

- A PO System must support user access right control so that multiple users can access it and roles can be assigned to view, write, approve POs.

- A well-designed PO System should be easy to use and support SME for use cases such as: trade, wholesale, manufacturing, sales and service, educational institutes, high-tech startups, etc.

Why Purchase Orders are Important for your Business?

There are many small and medium sized businesses that don’t use purchase orders because they feel like the paperwork is just a roadblock or unnecessary step in the process because they have steady working relationships with vendors. When small businesses are still in the startup phase, business owners tend to have an organic purchasing process that’s simple and straightforward. But, as the company grows, and more hands are involved from start to finish, the process changes as the relationships with vendors grow and evolve with time. At a certain point in company growth, purchasing demands become more complex, urgent, or specific, meaning communication can become difficult and leave plenty of room for error if POs are not used, or lack a certain level of detail.

Although PO system add a few extra steps to the purchasing process, they help to ensure a smooth transaction between the buyer and the seller. They also help reduce the risk of fulfilling an incomplete or incorrect spendings. In short, these documents are an opportunity for the buyer to communicate their request clearly and explicitly to the seller. On top of this, if the buyer refuses payment upon delivery of a good or service, the seller is protected because the PO acts as a binding contract between both parties. Lastly, some commercial lenders will use POs as a reference to provide financial assistance to an organization.

Tracking Purchase Orders

Purchase Order Tracking is important aspect of purchasing processes. It ensures that goods are received in time and in accurate quantity. It also ensures that you pay only once and in time for the goods that you buy. In addition, you should be able to put controls like beyond a predefined amount, a PO needs approval, and define the approval process. You can also assign PO budget for each department or account so that it can be properly monitored and controlled.

Spending management provides a better visibility of your supply chain. You understand when your items are arriving, so you can plan your sales fulfillment or manufacturing processes accordingly. It also helps you manage your vendors and source items in a competitive pricing.

An ability to track and easily report on all types of purchase orders, including blanket purchase orders, is a must to get full visibility on spend. It also enables finance departments to streamline the PO reconciliation and payable process. Visibility on the entire process, including an automated open purchase order report, will ensure time is saved and nothing is missed when invoicing.

Digital transformation is a key goal for many businesses and procurement transformation is a key part of that larger goal. An online PO system will track electronic POs through the entire process. You don’t need a dedicated purchasing department to feel the benefits of digitization.

What are Dropship Purchase Orders?

Many times, as a seller you create PO for your vendors or suppliers to fulfill your customer’s sales orders. In a normal process, the vendor sends items to you and then deliver items to your buyers. In some cases, you want your vendor to directly send items to your client. This type of buying is called drop ship purchase. Process wise, when you create a dropship purchase order, you provide your customer’s delivery address and instruct your vendor to send the invoice to you – not to your customer. In dropship PO, as a seller, you will not receive items from the vendor but should be able to pay to your vendor without goods received.

Example:

Customer: You are here because you are drop ship seller or supplier. Let’s assume you are a drop ship seller. A customer places an order to you. You create a SO for the customer. But you don’t fulfill it yourself. You have many vendors who ships orders directly to your customers. So, when a customer buys items from you, simply create a SO. And then follow the next step.

Supplier: Now you are ready to create a Drop Ship order with your vendor. You open the SO that you just created. You click on “Purchase” button on the top of the page. Then you click on the “Create New Drop Ship PO” button on the top of the page. Datamoto allows you to put customer’s shipping address in the Drop Ship PO. You send PO to your vendor and once accepted you notify your customer. Now your vendor can directly ship the items to your client.

Creating Multiple Bills from Purchase Orders

It is common that vendors always do not send all the items at the same time. So, it is necessary for a PO application to allow users to create multiple bills from one PO. Datamoto allows you to receive items in batches and create multiple bills or update an existing bill. This is a huge time saver – especially if you are currently using Quickbooks.

Budget and Purchase Orders

Accountant love to set up budgets for departments or teams for their spendings. It allows them to track the financial health of the company. Usually, they allocate a certain budget to each org or team and when a PO is created, it is assigned to one of the budgets (or cost centers). Automated ad-hoc reports show the remaining or overrun of the budget. Usually, this type of control is only available in sophisticated ERP applications. DATAMOTO PO application provides this.

Goods Receipt

When the vendor delivers goods, these are usually received in the PO application. You should be able to receive goods partially or fully. Also, if you maintain multiple warehouse locations, then you should be able to specify the number of goods to a specific warehouse location. This goods-receiving process must automatically update the inventory and generate the bill. Datamoto’s PO System comes with Inventory and billing and so these are automatically updated. It also allows you to print good-received notes which are necessary for certain use cases.

Purchase Order Approval

Purchase order approval is a common way of controlling expenses in a company. Usually, there are one or more than one approver is assigned to approve a PO. In some cases, a particular type of PO under certain values are auto approved. A PO approval system is a feature in a PO System software, which allows you to configure approvers and approval conditions for buying. Once it is configured, all PO go through this approval workflow. And if workflow determines that approval is required then it will start the process by alerting 1st approver. If approval is not required, then PO is auto approved. Most of the PO systems designed for small businesses do not provide this feature.

Purchase Requisition to Purchase Orders

Simply, a purchase requisition is an official document that is created to inform department managers or purchasing officers about a decision to make a procurement. This prompts the purchasing department to start the purchasing process. The finance team will also use this document to coordinate reporting procedures with the accounting department as well.

In any organization, there is always the need for supplies or materials and equipment. These may be office supplies, consumables, machines, and other equipment. But, when organizations allow departmental managers to buy directly from suppliers, it’s all too common for fraud to occur. To counter this risk, an organization will develop a procurement team, who dedicate time to placing POs with vendors on behalf of other departments. Most importantly, the purchasing team will follow a spending requisition workflow. This reduces the risk of fraud and creates an audit trail between these departments so that each person involved in a procurement can be made accountable.

What is Purchase to Pay?

The term Procure-to-Pay, also known as Purchase-to-Pay or P2P, covers three main processes in the procurement lifecycle: requisitioning, purchasing and payment.

From a technological point of view, Gartner defines Procure-to-Pay as follows: “As its name implies, a Procure-to-Pay (or Purchase-to-Pay) system is a fully integrated solution designed to support an end-to-end process that begins with goods and services requisitioning and ends with ready-to-pay files for upload into an accounts payable system. Procure-to-Pay solutions use a scan-and-capture service, supplier portal and/or a multi-enterprise network to enable suppliers to submit invoices electronically. In addition to core e-procurement functionality (including e-requisitioning, approval workflow and e-catalog management), Procure-to-Pay solutions offer purchase-order-to-invoice matching and processing for invoices that don’t match or when goods are returned.”

Procure-to-Pay solutions involve presenting suppliers’ products to users (using vendor catalogs) and then digitizing, automating, and enhancing the procurement and financial processes. They incorporate control, verification, validation, and document management activities, thereby allowing companies to exercise greater control over their procurements and improve their efficiency.

Converting Sales Orders to Purchase Orders

You are a small, medium, and large enterprise. You want to buy goods or services from a vendor or supplier. You must create a PO and give it to the vendor for the following reasons:

- Vendor needs a proof that you ordered the items.

- You need the PO so that your accountant can compare an invoice from vendor to the existing PO.

- A PO contains the goods or services requested, the cost of the services, the tentative date of delivery, and payment mechanism that are agreed between client and vendor. More on purchase order

A SO is used when you are selling goods or services to your client. A Sales Order Management Software usually combines Quote, Invoicing, and Sales Order. A SO tells you:

- Client details – including billing and shipping information

- The method and terms of shipment and payment

- The list of goods and services and their cost

If you sell goods to your customers and buy goods to fulfill your customer orders, then you will create both sales orders and POs. A common workflow that is used by many can be described as follows:

- You create a SO

- You then convert the SO to PO

- You create one or more POs from one SO. A PO is created for each vendor. This will link a purchase order to a sales order.

- You can now track your all POs for the SO.

- You can now track your SO from each of the POs created from the SO.

Why do you need automated Purchase Order process?

For efficient procurement and purchasing a good record keeping is essential, but paper-based records can easily be lost, damaged, or destroyed. It is more difficult to find duplicate requests and buys, invoices, and missing transactions, which cost your company both time and money. Paper-based process also require using an efficient filing system that needs a regular update. This filing system will take up considerable space in an office, only growing over time, and take up man hours to maintain and keep running smoothly.

Automating your purchase order process with a PO software that digitizes the entire procurement process by using electronic PO and other documents. All the important documents are tracked in a centralized system with an audit trail to tell you who takes what actions on the document. Plus, you can upload other documents to vendors, such as prior contracts, additional terms, and payment schedules, to keep track of all your vendor information and other details with ease.

With spending automation, everything is stored in a single system, the accounts payable department benefits as well, since it becomes easier for them to convert PO into bills for payment, for easier payment processing.

Purchase Orders and Inventory Management Software

Purchase order and inventory control is closely related when you buy goods from vendors. Your usual workflow for spending Management may contain following:

- You notice some of the items in the inventory are below threshold or not available. Or your client buys goods from you, and you realize you must buy the items to fulfill the customer request.

- You create a purchase requisite or PO to buy these items from vendors

- You create one PO per vendor to buy the items

- Your manager approves the PO. You send the POs to respective vendors.

- A vendor receives the PO and fulfill them accordingly.

- Items are delivered to your warehouse. You receive the items.

- When you receive the items, the quantity of items is added in the inventory management system. Inventory management system also put the link to PO so that it can track from which PO these items’ quantities are added

In the above purchasing process, you can see how inventory management system and PO Systems are related. In fact, inventory management software also provides PO functionality. Similarly, a PO system also provides inventory management system.

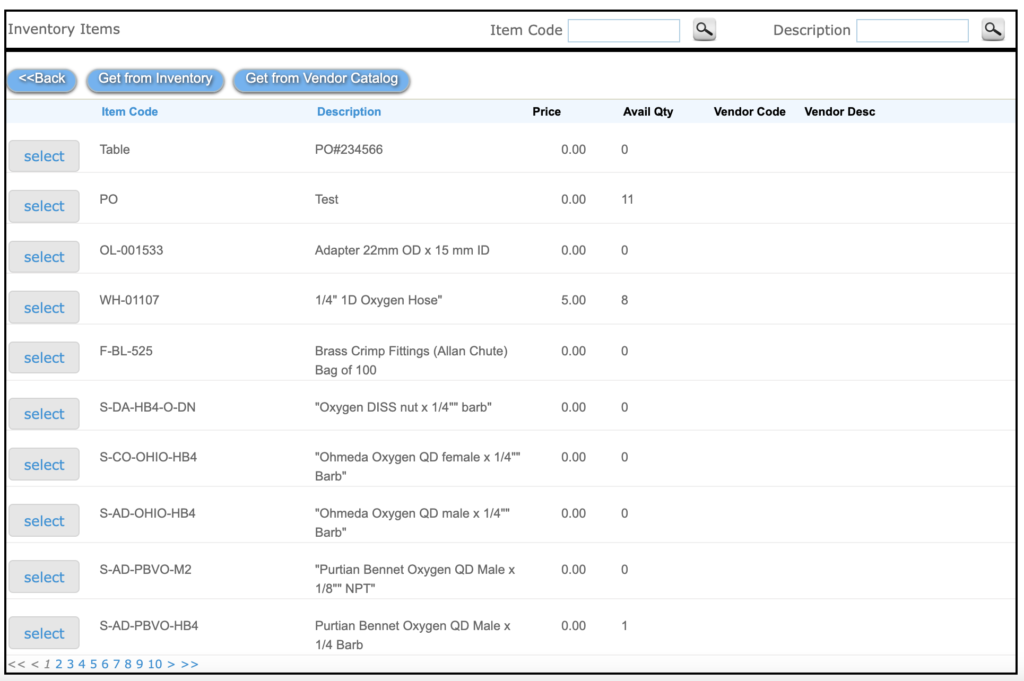

How a Vendor Catalog relate to Purchase Orders Control System?

A company often maintains vendor catalogs for items to buy by its’ employees for internal purpose or for its’ customers. For a small business, often Vendor Catalogs are used to buy goods from suppliers to fulfill sales orders. A PO System should allow a user to buy items from a specific vendor catalog. Catalog purchase orders are easy to create and less error prone since system can automatically bring the vendor item code, item description and price for the item from the vendor catalog in the Purchase Order Control system. More on creating purchase orders from vendor catalog.

What is the difference between ERP and Purchase Order System?

Enterprise resource planning (ERP) refers to a type of software that organizations use to manage day-to-day business activities such as accounting, procurement, project management, risk management and compliance, and supply chain operations. Basically, ERP System provides the foundational building blocks and template modules to drive various business operations in an organization. ERP System often needs to extensively configure and extend to satisfy specific user use cases. So, this is not really an out of the box solution. Also, organization often only implement few specific modules in the ERP System – accounting module is the most popular module you will find in ERP.

PO System is one of the modules which is part of the ERP System. There are also many PO Systems which are not part of the ERP System. The independent PO Systems are usually out-of-the box solution requiring zero implementation. These independent PO System often are integrated with accounting system (independent or ERP) for invoicing and billing.

What are the differences between Purchase Orders and Invoices?

Both purchase orders and invoices contain similar information, such as a billing address, and shipping address.

Invoice is usually a document issued by the seller to the buyer showing items which have been sold, payments, and signatures of buyer and seller. Invoices typically reference the purchase order number, with the addition of an invoice number to confirm that both documents are related and correspond with one another. It shows that the buyer has some money to give to the seller after showing the list of products the seller grants to the buyer. Many invoices these days are issued using online software.

Here are a few differences between POs and invoices:

Purchase Orders

- Created by the buyer

- Created before buying

- Lays out goods needed

- Includes proposed payment details

Invoices

- Created by the seller

- Created after buying

- Confirms goods delivered

- Requires payment on a specific date

Making use of an invoice helps you to track the money you make and your expenses as a seller. It also helps in inventory checking and management and helps you to calculate the profit made. They also serve as a reference for all your business transactions and gives you a measure of control over your business and to monitor your progress.

Whereas a PO is a document that is sent from the buyer to the seller or vendor to grant a purchase. A PO indicates the items the buyer decides to buy and the prices. Sometimes the PO may allow a company to buy a particular product as many times as possible for a certain period. Many purchasing systems exist today which can record what has been ordered, what has arrived and what is not invoiced.

The Differences between Purchase Orders and Sales Orders

A PO is a document sent to a supplier when you or someone in your company buys something. A PO indicates the items the buyer decides to buy and the prices.

A SO is a document generated by the seller specifying the details about the product or services ordered by the customer. Along with the product and service details, SO consists of price, quantity, terms, and conditions etc.

Similarities between Purchase Orders and Sales Orders:

- Both POs and SOs have the list of goods and services that will involve in the transaction listed on them.

- Both POs and SOs are legally binding documents when the receiving party of either document accepts it.

- Both POs and SOs are widely used in business to business (B2B) transactions in industries such as manufacturing, wholesaling, and retail.

Differences between Purchase Orders and Sales Orders:

- POs are created and issued by the buying party, while SOs are created and issued by the selling party.

- A PO is sent to the supplier without the SO number on it, while the SO is sent to the buyer with the PO number included on the SO document (a SO which has a purchase order number on it acts as a supplier’s compliance with the terms of the PO).

- In some instances, an SO may be sent to a buyer to confirm a procurement, without a PO being sent to the supplier first. Some purchasing policies inhibit this type of purchasing behavior within an organization, such as the “No PO No Pay Policy”.

Example:

In many B2B cases, when a customer buys items from a seller, the seller must first buy items from other vendors to fulfill the order. Here is an example of process that is followed by the seller:

- Seller creates a SO and sends to the customer. It clearly tells item, quantity, and price.

- Seller checks and finds some of the items are not in the stock. So, he finds vendors who can supply those items.

- Seller creates one or more POs (one PO for one vendor) which clearly marks the item, description, and price along with shipping address. These POs are sent to the vendors.

- The Seller link these POs to the original SO so that it can track the delivery from vendors.

- Items delivered by vendor are received in appropriate warehouse and a bill is generated. The vendor’s invoice us attached to the bill so that Account Payable can pay to the vendors.

- Once items are received, the SO is fulfilled, and items are delivered. An invoice is issues to the customer for payment.

More on the differences between purchase orders and sales orders.

How Purchase Orders are different from Work Orders?

A company creates PO for the goods and services that it wants to buy from a vendor or supplier. A vendor needs a PO to fulfill the request. The key characteristics of a PO are:

- It contains vendor or supplier information

- It contains goods and services that are ordered, their quantity and cost

- It contains information about delivery mechanism and payment methods

A vendor uses the PO from the client to invoice then client for the goods and services it delivered.

On other hand, a work order is a ticket that a service provider creates when it receives request for a work to be performed from a client (what is work order?). A work order also known as service order (field service management software), can be created on client’s request, or can be automatically generated by the system – especially for scheduled maintenance work, and can be generated by the system by predicting that a machine may fail very soon and so a maintenance on the machine is required. Work order is mainly use for sales and service, installation and maintenance, manufacturing, construction, and other industries. The key characteristics of a work order are:

- It contains detailed information about the client

- It contains information about time to perform the job and field service technicians assigned to the task

- It may also contain material use for the task

- It may also contain task performed including if any quote, invoice, or PO are generated for the task

- It tracks the time spent on the specific task

More on the work order management software.

How to Integrate Purchase Orders into Your Business

Begin by evaluating how your business currently handles purchasing and then consider how you’d like to control what your team can buy and how they’d process the entire procurement process. After that you will be able to create a PO system that is suitable to your company’s needs.

Purchase Order Best Practices for Small and Medium Sized Businesses

Ensuring you have robust purchase order terms and conditions covering all relevant scenarios, including details like when you can cancel and return a purchase order, will ensure clear boundaries to maintain good relationships with your key suppliers.

Follow these purchase order best practices when you create a process for PO for your small and medium sized business.

Adopt an electronic purchase order system:

Consider adopting an online purchase order system. An online PO System will save you the hassle of using manual Word and Excel template to create POs and make it much easier to track the goods receipt and payment to the vendors. Moreover, not only do these electronic systems prevent you from misplacing or damaging paperwork, but they also provide an environmentally friendly alternative to printing all the documents involved in a purchasing cycle.

Set budget for your expense categories:

According to your yearly budget, you may have allocated a set amount for each business expense category such as office equipment to product supplies and equipment to outside services and more. As such, establishing clear expense categories can be helpful for better tracking your cash flow. It may also help to set pricing thresholds so that POs remain within the bounds of your business’s budget, e.g., capping equipment purchasing at a certain figure.

Use a purchase approval system:

Enforcing a purchase order approval workflow can help prevent spending from getting out of hand, especially in the event duplicate buying requests are placed for the same product. To avoid scenarios of this nature, appoint a purchasing manager to approve POs before they’re submitted to your vendor. Establishing an approval workflow helps to control organization costs and prevent financial mismanagement.

Create a vendor catalog:

Consider creating a spreadsheet directory of all the different suppliers your business buys from, with all the information necessary to complete an PO, e.g., address, contact number, payment terms. Having this database can streamline the purchasing process by acting as a reference and guide for the best supplier to buy from. It can even help in deciding which vendor to move forward with in the event you want to establish a long-term contract.

Write up a PO guide for employees:

Having a PO guide on hand establishes ground rules and expectations for your team when making purchasing decisions on behalf of your company. For instance, should employees always select the lowest priced goods to cut back on business expenses? Or should they opt for more expensive goods to account for quality? Perhaps there’s a particular rule of thumb you want to enforce for a more consistent purchasing strategy among your team members. In any case, a guide serves as a useful reference to not only outline procedures for more specific purchasing scenarios but to also train new employees in choosing and negotiating with vendors.