What is a Work Order? A simple work order management software is explained

A work order is usually a task or a job for a customer, that can be scheduled or assigned to someone. A work order may be for products or services. In a service environment, an order can be equivalent to a service order where the WO records the location, date, and time the service is carried out and the nature of work that is done. In a manufacturing environment, a work order is converted from a sales order to show that work is about to begin on the manufacture, building, or engineering of the products requested by the customer. More on it

A work order may include one or more of the following:

- Instructions

- Cost estimates

- Forms

- Date and time to execute the work order

- Information about the location and entities to execute the work order and

- The person to whom the work order is assigned

Small businesses or enterprises use the same type of work order application. Many times, field service software application can provide both field service as well as manufacturing work order functionalities.

A Work Order Workflow

Below is a sample work order workflow for field service:

A Work Order Software (Field Service Management) helps drive the sales and services of field service workers. A Work Order Management application must be integrated with the Inventory and Purchase Order Management system to drive end-to-end operations. Below is a typical workflow:

- Steve, the Facility Manager of Stanford Hospital calls Gregory Medical Supplies to provide immediate service to an Anesthesia machine.

- Diana, the office manager of Gregory Medical Supplies creates a work order for Standford Hospital.

- Since the said Anesthesia machine was previously serviced by Gregory Medical Supplies, Diana finds the record of the asset in the client asset inventory and assigns it to the newly created work order.

- Diana looks for available resources in the Work Order application and assigns Bob to the job for the 3 PM to 5 PM time slot.

- Bob gets the alert of his new job assignment. Then he checks the service order detail and also past services that were performed on the Anesthesia machine.

- Bob checks inventory for available spare parts in the Work Order Software. As a result, he notices that few spare parts are not available in his truck but available in the central inventory. So, he drives to the office to load those parts in the truck from the central inventory

- While loading the spare parts in the trucks, he makes sure to transfer those spare parts using the Inventory module in the app

- At 3 PM Bob reaches the Standford Hospitals and performs the maintenance of the Anesthesia machine. He uses Anesthesia Maintenance Checklist to perform all the maintenance procedures and notes all the measurements

- Bob updates all the work he performed in the Work Order Management application

- He updates the app with spare parts used

- In the end, Bob asks Steve to sign the work order to confirm the services he performed

- Bob generates PDF report and invoice for the service and emails to Steve

Demo

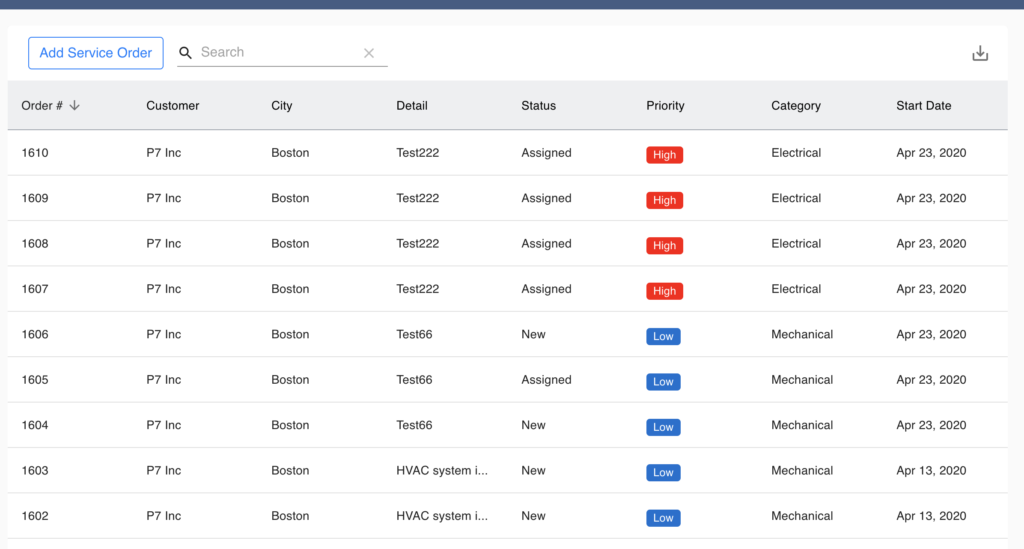

Let’s have a look at the field service order execution demo from Datamoto. This demo shows how a work order is created and a field service engineer used the field service app to perform the job. The app also enables tracking of the activities performed on the work order.

Datamoto’s Field Service Management App

Manufacturing Work Order

Datamoto provides a very simple use of the complete life cycle of order management for manufacturing organizations. It allows users to create sales order directly or convert a quote to a sales order. Users can book the order, create a work order, and send notifications to customers about the order. Work orders are created from the sales order. It contains information about the products and instructions to manufacture. Also, it does not contain the price information and which can be sent to the manufacturing unit to manufacture the goods. More on the manufacturing work order

More on Types of maintenance work orders

Field Service

The Datamoto Field Service Management solution empowers technicians to boost customer satisfaction with an app that is fully integrated with the Inventory and Order Management solution. Some of the features of the Field Service Management App are described below:

- Schedule Resource Intelligently

- Dispatch the right technician at the right time

- Assign team members in one work order

- Better manage resource assignments by using a drag-and-drop scheduling board

- Match technician’s skills with job requirements

- Schedule machines such as crane at the construction site

- Timesheet to keep track of time spent by resources at the site

- Easy reschedule of work order

- Work Order Management

- Add multiple pieces of equipment in an order

- Also, add service notes in the work order

- Track parts at each stage of the order

- Find vendors for the parts from a vendor catalog

- Locate parts and cost in the truck or other warehouse locations

- Minimize repeat visits by ensuring parts availability

- Create a purchase order for multiple vendors with a click of a button

- Create invoice with complete flexibility of editing quantity and cost

- Take pictures of the job with your iPad or Phone

- Sign the order on the phone

- Send a full PDF service report to the customer

- 360-degree View of Customer Assets

- Asset management

- Organize assets by org for better tracking

- Track and manage equipment and inventory

- Effectively schedule maintenance to minimize maintenance and repair costs

- Reduce asset downtime due to equipment maintenance or failures

- Assign equipment and inventory to specific employees or department

- Track all the service orders and service reports associated with the equipment

- Keep track of user manuals and documents for the equipment

- Capture key identifying information about equipment to facilitate warranty claim assessments, retrofit and revision needs, recalls, and more

- Material, Inventory, and Order Management

- Search parts in the bin, truck, or warehouse

- Complete visibility of available quantities and costs

- Find easily the vendors to purchase the parts from Vendor Catalog or from general Vendor List

- Create purchase order per vendor and edit before submitting for approval

- Invoice the services provided with the parts

- Invoice the parts that used in the order – automatically adjust the quantity in the right warehouse

- Create estimate – automatically imports service notes and materials needed for the job

- Create sales order – automatically imports service notes and materials needed for the job

- Build multi-currency vendor catalog as you go

- Mobile app

- Equipment Recall Report for Medical Equipment

- Equipment search by manufacturer, model, and serial number

- Ability to search by serial number range

- Provide detailed equipment reports and status of the equipment

- Generate the report instantly – at the back office or on the road

- Download the report with the client contact information

- Enterprise Connectors – Dynamics 365, NetSuite, Oracle, SAP, Salesforce, Workdays

More on field service management

Types of maintenance work orders

There are different types of Maintenance work orders. Usually, the category of work orders is defined by how they are created. Some of the jobs that are performed are called planned jobs. There are like routine maintenance jobs. Other types of jobs are unplanned. these are the emergency type of repair jobs.

Based on the type of problem that needs to be addressed, an order can be categorized as:

- Unplanned work order: There are used to address unplanned maintenance activities like unexpected machine breakdown

- Planned work order: These are used to schedule preventive maintenance work

Some organizations also divide orders depending on where the job requests are created:

- Internal work orders: When a job request comes from someone inside the organization

- External work orders: When a job request comes from someone outside the organization

Most of the work orders are manually created. This means someone actively creating the order ticket. In some organizations, the Internet of Things (IoT) is used to automatically create work orders.

Planned work orders are usually created using a scheduler. The scheduler is usually flexible enough to set and edit the order creation logic. The orders are created as per schedule for planned maintenance. These service orders then assigned to service engineers to perform the task.

Tracking Work Order

- Order tracking is important to schedule it and monitor its progress.

- It helps to see what type of works are performed on the assets.

- The tracking also provides information about the POs and invoices created for the job.

Performing on Work Order

- While working on an order, a service tech may need to access inventory. More on the Purchase order and Inventory

- When working on a job, a service tech may need to create an invoice or sales order.

- While working on a job, a service engineer may need to transfer spare parts from one location to another. More on Stock transfer between warehouses

Customer Success Story of Small Business

Automated the scheduling of construction workers and equipment at the construction site and generate timesheets and invoices.

Company: A Texas-based company executing gas infrastructure projects

Pain Points:

- Difficult to schedule a team of workers in a construction site

- No visibility of equipment in various construction sites and their schedules

- The manual process of the timesheet

- No proper integration with the accounting system

Implementation:

- Implemented Datamoto Field Service Management solution

- Used Datamoto scheduling to schedule individual or team of construction workers

- Also used scheduling to schedule equipment such as cranes in various construction sites

- Generate and approve timesheet through the system

Achieved:

- Centralize scheduling and complete visibility

- Invoice sync to QuickBooks online for faster payment

- An auditable system of records

Business Outcome:

- The site leader is able to manage the site efficiently and so minimizing the disruption

- Better utilization of equipment and so increase of revenue

About CMMS

A computerized maintenance management system (CMMS), also known as computerized maintenance management information system (CMMIS), is a software package that maintains a computer database of information about an organization’s maintenance operations.

Maintenance professionals use CMMS software to plan, manage, and improve plant and facility maintenance, and to standardize operations. When used maximally, it extends equipment life, reduces overall costs, and increases asset reliability and productivity. There are countless benefits to using CMMS software. Here are just a few:

- Automate recurring preventive maintenance tasks saving time

- Easily document and assure regulatory compliance

- Digitalize forms and other documents while eliminating paper

- Organize inventory and optimize spare parts availability

- Gain a comprehensive view of asset health and identify issues early

A CMMS stores asset data and associated maintenance-related activities and documents in one central location. With web-based maintenance software, teams can access and view asset repair histories and send and receive work requests and work orders from almost anywhere—via mobile phones, PCs, laptops, or other smart devices.

Further reading: