Manufacturing Inventory Management Software

What is Inventory Management?

When you use an inventory management system for invoicing – you are using an inventory invoicing software. An invoice is a document that records a transaction between buyer and seller. When a seller creates an invoice for a customer, it includes company information, the invoice number, invoice date, itemized list of the purchases the customer has ordered, and others. This itemized list can be for services or products, or both. As a manufacturing or retail business, invoices will be for goods sold.

-

Receive purchases

-

Pick, pack and ship sales

-

Quoting and invoicing

-

Returns management

-

Reordering

-

Serial number tracking

-

Lot ID tracking

-

3rd party integrations

-

Kitting/bundles

-

Manufacturing — Bill of Materials (BOM)

-

Label printing

-

Customized data fields

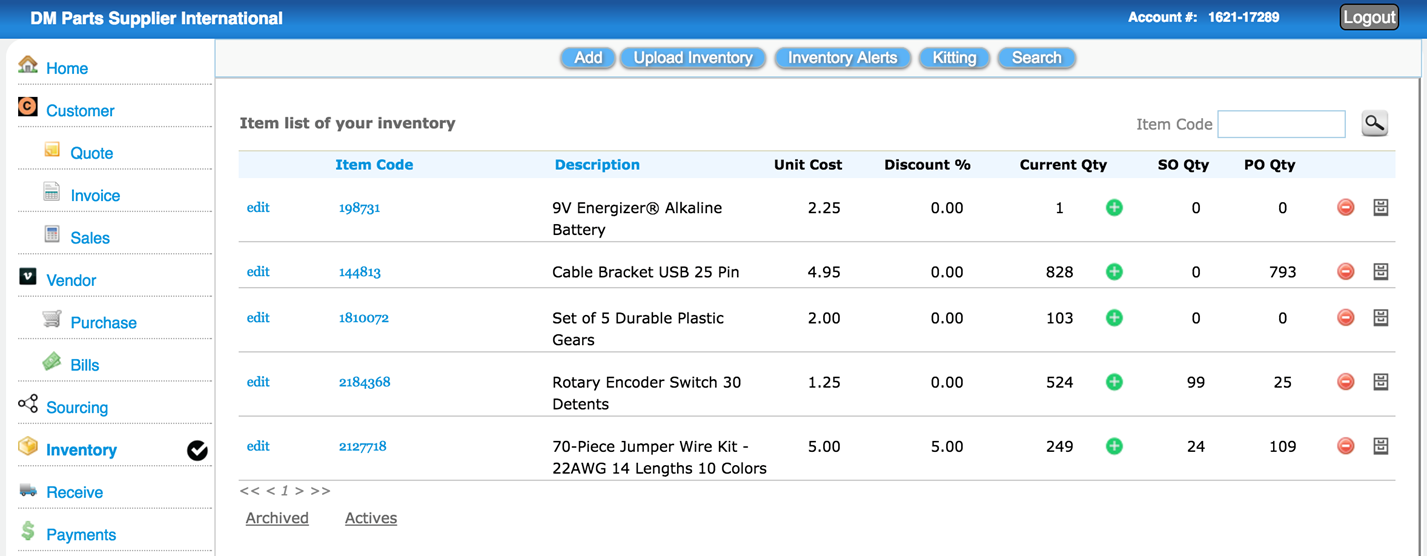

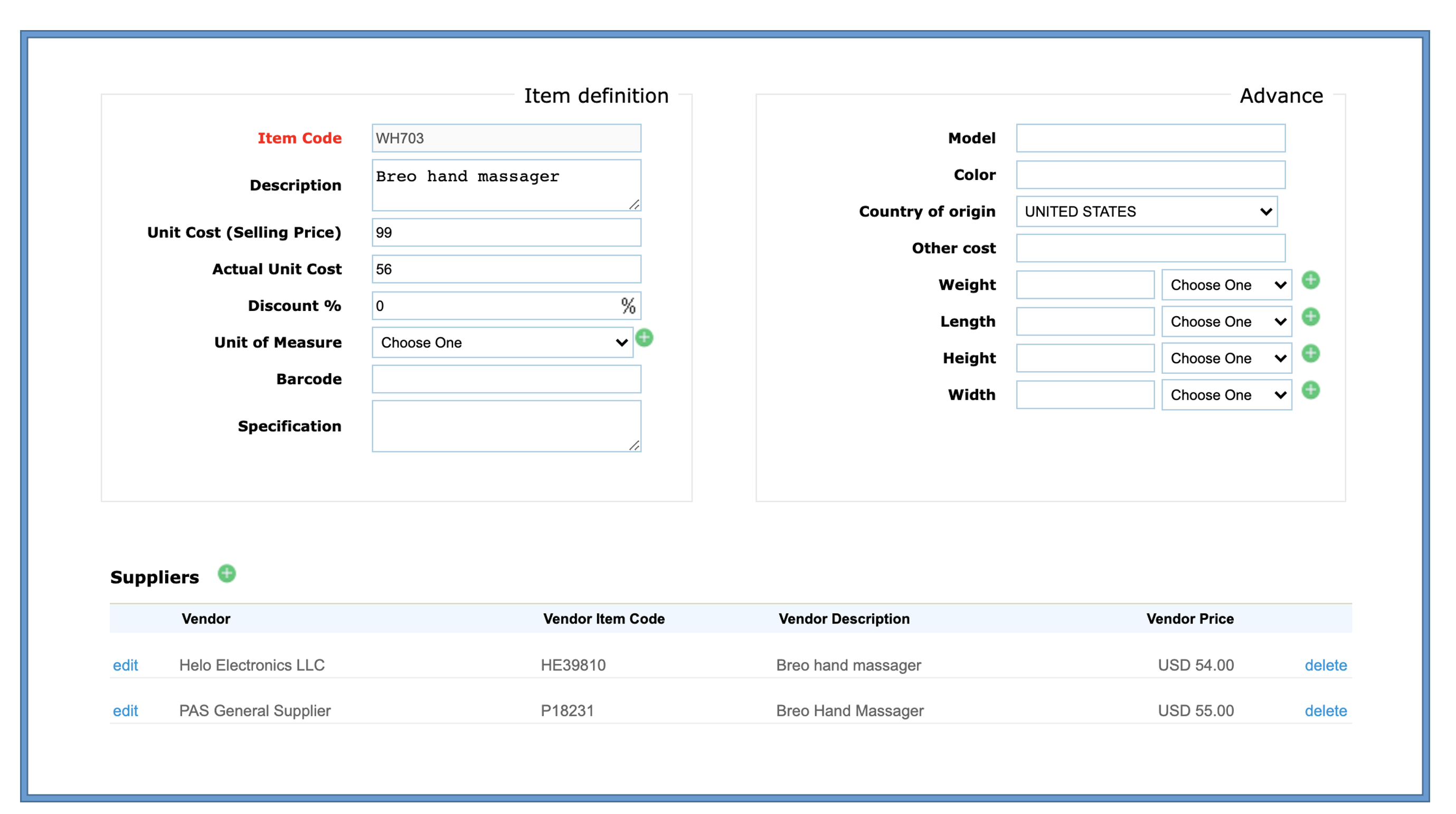

Inventory Item Definition

A product or item is what exists in the inventory system. Usually, item code, description, selling cost, purchase price, discount, quantity, unit of measure, barcode and specification are the basic definition of an item that all inventory control system provides. Find more: inventory invoicing software

Unit of Measure

The unit of measure for items depends on the type of inventory is kept. It is necessary the system should allow adding, removing, and editing units of measure according to the need.

Inventory Configurations

Depending on the vendors, an inventory system may provide different types of configurations.

Inventory Stock Alert

It is important for businesses to get alerted when stock runs low for items. The stock threshold could be set up at a global level — that is one stock threshold for all items or individual item level. When the stock level goes below the threshold then alerts are generated where you can covert an alert to purchase order. This helps uninterrupted inventory operations.

Update Inventory from Sales Order Fulfilment

The ability to split an order to deliver items in multiple batches as well as merge multiple orders to one shipment is a very important feature for order fulfillment. This feature optimizes the complex fulfillment process.

Lot Tracking

Every use case does not require inventory tracking using lot numbers. But some business use case especially for pharma or cosmetic — it may be required. In such cases, you should make sure you have the ability to add inventory stock according to the batch number.

Bundle/Kitting

Inventory Item Bundling or Kitting is a process in which individually separate but related items are grouped, packaged, and sold together as one unit. For example, in ordering a PC online, a customer may select memory, drives, peripherals, and software from several alternatives. The supplier then creates a customized kit that is assembled and shipped as one unit.

API For Inventory

Datamoto supports APIs for inventory, sales orders, invoices, purchase orders, quote, and others. There is a limit to how many APIs can be called per day which can be adjusted according to the customer’s need. This is a very useful feature for e-Commerce.

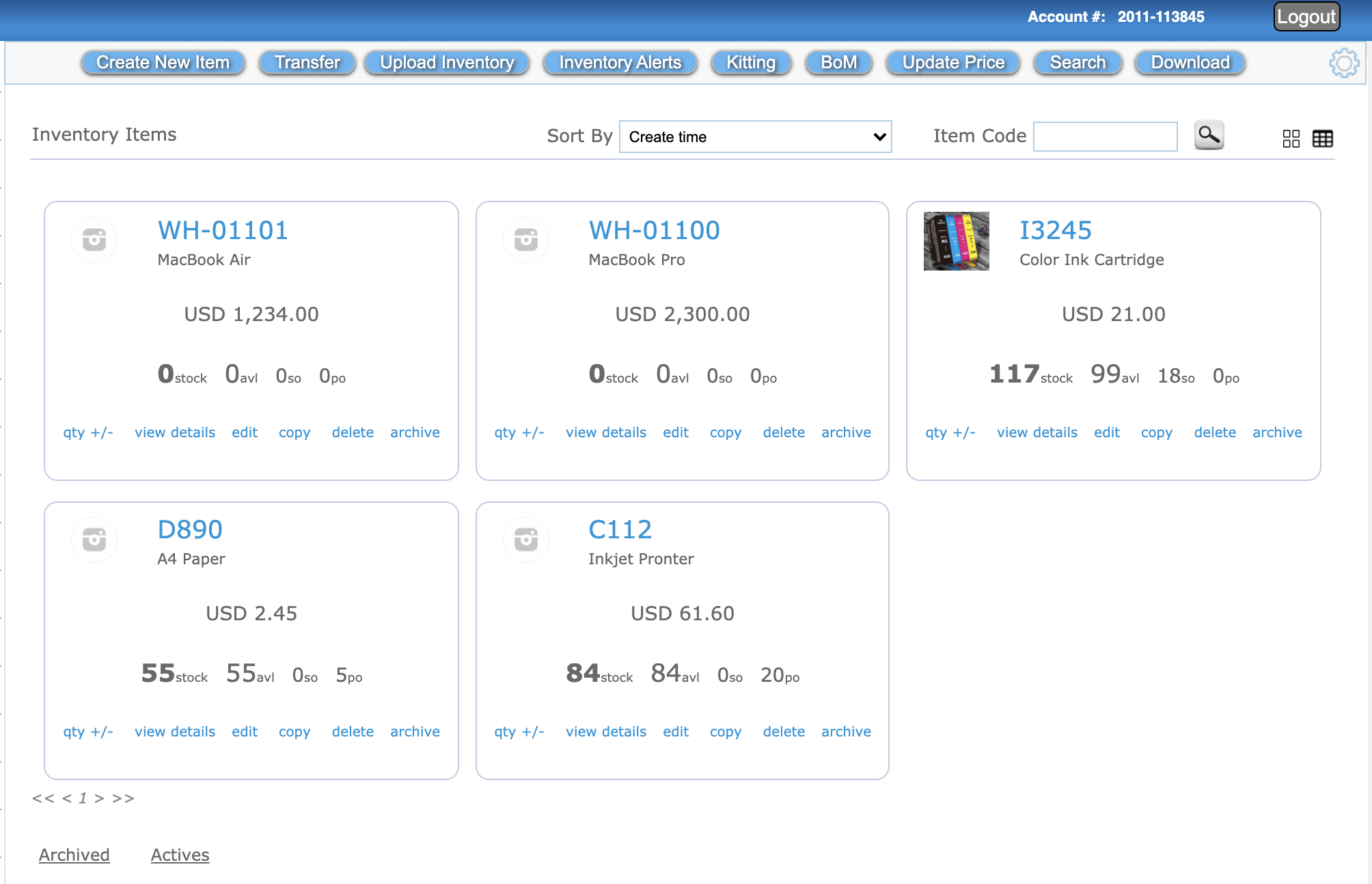

Active and Archive Items

Sometimes, you may stop maintaining some of the items. For such items, you should able to archive them so that they will be kept aside from the view while you can still run the report on them. The system should provide the ability to view archived items and make them active if needed.

Warehouse Locations

Businesses’ operations often need to handle multiple warehouse locations. This means the inventory management software must able to look up items across all warehouse locations, able to receive delivery or pickup from any locations, transfer stocks between locations. All the purchases and invoices must be able to track the inventory items.

Image for Items

For e-Commerce, you may want to maintain multiple images for your items. Datamoto allows you to upload up to 3 images per item.

Manual Update of Stock

If you are managing a warehouse then you are familiar with that manual update of stock level is inevitable. Sometimes, items are misplaced, and other times it is hard to reconcile the actual count (or cycle count) and the count in the system. So, a manual update that can be audited is a required feature to run a warehouse smartly.

Update Inventory from Purchase Order Goods Receive

A good receive functionality allows you to record every good receive for POs and similarly, these received goods are automatically added to the inventory and recorded to a specific warehouse location.

Inventory Tracking

Inventory tracking is a large area that may include finding out the location of an item in the warehouse. But, here scope is limited and we are discussing tracking how your inventory items’ stock level affecting. Who is adding items in the inventory, who is picking up the items from the inventory? Having an audit trail of every addition or subcontract of an item’s stock level is a must for an advanced inventory system. It should tell you which purchase order delivery added the stock and who was the item receiver.

Stock Transfer Between Warehouses

If you are a trader, distributor, wholesaler, or seller who maintains multiple warehouses then you may want to transfer inventory items from one warehouse to another. If you maintain batch or lot number then you may like to transfer items by lot and track the transfer. Transferring stocks between two warehouses is done through two separate transactions.

Bill of Materials

A bill of materials or product structure (sometimes bill of material, BOM, or associated list) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and quantities of each needed to manufacture an end product. An inventory management software with a bill of materials allows creating BoM for a product by adding items or raw materials and instruction notes. When products are produced these are added to the stock at hand whereas the stock levels of the items in the BoM are deducted.

Our Inventory Management Solutions

Datamoto helps you run your manufacturing efficiently.

INVENTORY – LOT TRACKING

Items kitting, bill of material, track item activities, set alerts for re-order, lot or batch tracking, multiple inventories, transfer between warehouses, link to sales and purchase orders, more on Inventory Management Software

BILL OF MATERIALS

A robust manufacturing inventory management software to create BoM adding other items or raw materials defined in the inventory. When items are produced these are added to the stock at hand whereas the stock level of the items in the BoM is deducted, more on Bill of Materials

PRODUCTION WORK ORDERS

Generate simple production work orders from the sales order for the manufacturing job. Automatically BoM information is transferred to work order. This helps manufacturing or assembly technicians to have complete information on the work order.

INVOICE & QUOTE

Create, track and manage quotes, invoices, and payments online. Handle export invoices, foreign currencies, generate PDF, and Email support. Customizable invoice. Integrated with Inventory and sales order system.

SALES ORDER

Create sales order, fulfill order (split or merge orders), packing list, handle return and cancel. Accept advance payment or Layaway. Automatic Quote to Order and Order to Invoice. Create and track purchases for every sales order.

PURCHASE ORDER

One-click purchase order creation for every sales order. Purchase orders can also be created from inventory alerts. You can manage purchases with budget control and multi-level approval. Receive delivery and generate bills. Process returns. Inventory to Purchase Order

CONTACTS & REMINDERS

Log all communications with customers and vendors. Set the reminders. Log these communications at document level or at customer/vendor level and optimize customer/vendor relationship.

PAYMENT & REPORT

Keep track of payments from your client and bill from your vendors. Many useful pre-built reports to check finances, inventories and operations.

AUTOMATE

Transform

Break through your limitations with the technology built specifically for distributors and manufacturers. A cloud based application built for 21st centuries companies.

Engage

Engage and inspire your customers by providing services that they deserve with efficiency.

Order

Datamoto online order life-cycle management software puts you in a faster path to recognize revenue, higher customer satisfaction and renewals.

Source

Leverage supplier and vendor relationships with complete visibility across the purchasing process.

Warehouse

Streamline your storage with deep metrics and inventory controls. Turn your warehouse faster.

Fulfill

Deliver on time, every time. Exceed your customers’ expectations while minimizing shipping costs.

Key Features of Manufacturing Inventory Software

Manufacturing inventory invoice software is an important tool that enables manufacturers to minimize costs and optimize operations efficiently. It allows manufacturers to instantly create bills of materials, sales orders, production orders, maintenance work orders, and more to simplify the manufacturing process. With the manufacturing inventory software, manufacturers can monitor inventory levels in real time, replenish inventory through stock alerts, and manage inventory in multiple warehouses.

-

Multi-location warehouses

-

Bills of Materials for Manufacturing Jobs

-

Sales Order to Production Work Order

-

Order Merging and Splitting Using Manufacturing Inventory Invoice Software

-

Dropship To End Customer Directly

-

Automatically Generate Purchase Orders From Inventory Alerts

-

Create Maintenance Work Orders

-

Print Packing List and Invoice for Delivery

Multi-location warehouses

Manufacturing operations often need to handle multiple warehouses. This means the manufacturing inventory software must able to lookup items across all warehouse locations, able to receive delivery or pickup from any locations, transfer stocks between locations. All the purchase orders and invoices must be able to track the inventory items. Datamoto inventory tracking system provides all the above functionalities. More on inventory transfer

Bills of Materials for Manufacturing Jobs

Bills of materials in manufacturing are a way to manufacture or assemble products. A product may contain multiple other items which are assembled together. A bill of materials clearly notes items and quantity that are needed and also instructions for plant operators to assemble or manufacture the product. Once a product is manufactured and added to the inventory, the items used to manufacture it are automatically deducted from the inventory.

Sales Order to Production Work Order

Usually, a sales order contains product, quantity, cost, and customer information. A sales order can be converted to production and pass them to the plant operator to manufacture the product. A production order will contain detailed information of the bills of materials including assembly or manufacturing instructions.

Order Merging and Splitting Using Manufacturing Inventory Invoice Software

Datamoto manufacturing inventory invoice software provides a fulfillment process where you ship or fulfill the items ordered. It provides a very sophisticated yet simple fulfillment tool to fulfill orders such as: partially, splitting quantity per line item, combining (merging) multiple orders, and fulfill complete orders. When you fulfill an order, the Datamoto sales order management module searches the database and provides you a list of other sales orders from the same customer which are booked (or not completely shipped yet) and has the same shipping address. You can choose to complete fulfillment for all these sales orders in one fulfillment which will create only one shipment and generate one invoice. More on sales order fulfillment

Dropship To End Customer Directly

You get Drop Ship requests from a B2C company and you ship the order to the customers of the B2C company directly. To do so, in the packing list you must put the B2C company’s name in the from section since the end customer only knows the B2C company.

When you get a drop-ship order, in Datamoto Manufacturing Inventory software you go to the sales order module, and click on “Create New Drop Ship for Supplier”. Select the customer. Change the Shipping address. The rest of the process is the same as any other sales order creation and fulfillment. When you fulfill this order, it will put B2C company as from address and actual client’s name and address in the Shipping and Billing in the packing list.

-

More on drop-ship order

Automatically Generate Purchase Orders From Inventory Alerts

It is important for manufacturing to get alerted when stock runs low for items. The stock threshold could be setup global level – that is one stock threshold for all items or individual item level. When the stock level goes below the threshold then alerts are generated with a purchase button for easy order. This helps uninterrupted manufacturing operations.

Create Maintenance Work Orders

In a manufacturing plant, it is normal to have planned or unplanned maintenance or servicing. A maintenance work order management software (CMMS) allows you to plan and create work orders, schedule and dispatch workers, and more in the manufacturing plant.

Print Packing List and Invoice for Delivery

Once the products are manufactured and ready for delivery, the packing list needs to be printed along with the invoice for delivery. These are automatically generated and printed as the sales orders are fulfilled. This helps the manufacturing plant to ship goods as fast as possible.

Pharmaceutical Supplier: How am I using Online Datamoto Inventory?

Robert Philmen

General Manager | Essential Medical Supply

Problem:

In the pharmaceutical industry, it is required to comply with the governments or manufacturers recalls. Tracking of every item purchased and sold by their lot (or batch) numbers is the must for recall. Robert was using an online software for order management which did not provide lot tracking. Also, he needed split order fulfillment functionality which was not available in the software. He wanted an ERP like system but cost and complexities are so high, his medium size company couldn’t afford it.

Solution:

“Datamoto helped us to migrate our existing data into their system. We migrated all our data within two weeks. Now we can generate recall reports instantly. Moreover, Datamoto is so easy to use and powerful, it has optimized our order management operations tremendously and increased the productivity”, says Robert. The following business processes are used to solve Robert’s problem:

- Customer and inventory data were extracted from existing system, reformatted and uploaded to Datamoto.

- Company logo, account number generation configuration, tax, shipping methods, payments terms, email templates, warehouses were all configured.

- Enabled the lot tracking.

- 30 users were added with various access rights such as purchase, sales, reports and so on.

- One hour remote training session for all users.

Frequently Asked Questions

Here are some commonly asked questions related to Manufacturing Inventory and Invoicing solutions from Datamoto

Q1. What are the licensing model for Datamoto’s Manufacturing Inventory and Invoicing solution?

A. The Trader billing & invoicing solution is licensed on a subscription model. Please check here.

Q2. How does my manufacturing invoicing system get managed?

A. Datamoto runs its manufacturing invoicing platform and applications in the cloud. All the data are managed in the cloud by our IT staff.

Q3. Is my data secure?

A. Yes, We take the complete backup of the manufacturing system on the regular basis. We have scalable network architecture, provision of disaster recovery & infrastructural facilities powered with the latest hardware and software.

Q4. Can I generate reports?

A. Datamoto provides many reports for manufacturing invoices, billing, accounting, and inventories. These are inbuilt reports. You can simply change the data range and get the report immediately.

Q5. Does manufacturing need a purchase order application?

A. Yes. The manufacturing business process involves buying raw materials, and parts to create or assemble a product. So a manufacturing plant needs a purchase order application.

Q6. Does manufacturing need a maintenance work order application?

A. Yes. A manufacturing plant needs maintenance. To schedule and perform the maintenance, the manufacturing plant needs a maintenance work order application.

Manufacturing Inventory Software Price Update Demo